Jun

Replacing guides on a telescopic rod - Professional guide

Replacing the guides on a telescopic rod requires some patience and precision. This procedure is not exactly a routine operation and should be carried out carefully to preserve the structural integrity of the rod. However, sometimes it is worth investing a little effort and repairing the rod you have instead of buying a new one. We have a large selection of ceramic guides in our offer and they are currently on sale!

Follow this guide step by step.

1. Preparing the workspace

- Ensure a clean, well-lit work space

- Prepare all the necessary tools in advance:

- Pointed tweezers

- Mechanical hair dryer (with low temperature option)

- Two-component adhesive

- Medical alcohol 70%

- Soft, lint-free cloths

- Precision screwdriver set

2. Dismantling the rod

a) Initial inspection:

- Examine the rod closely to identify all connection points.

- Note the position of each guide.

b) Disassembly procedure:

- Place the stick horizontally on a soft surface.

- Unscrew the bottom cap (foot) counterclockwise

- Separate each segment gradually:

- Hold the segment firmly but without applying force.

- Loosen the joint with light rotating movements (5-10°).

- Avoid sudden withdrawal

3. Removing existing guides

a) Thermal loosening:

- Set the mechanical hair dryer to 60-70°C.

- Heat the area around the guide evenly for 15-20 seconds.

- After warming up, wait 10 seconds before manipulating.

b) Extraction:

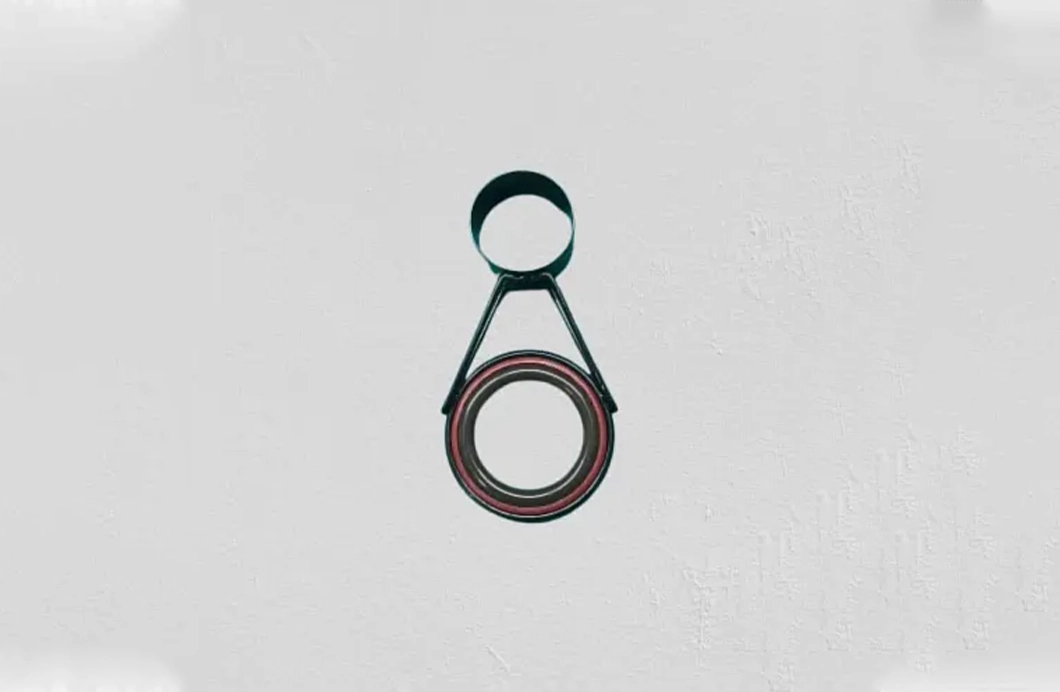

- Use tweezers to grasp the base of the guide.

- Apply an even pulling force along the rod axis.

- If necessary, use a scalpel, preferably sharp.

4. Preparing surfaces for the new guide

- Clean the bearing surface thoroughly:

- First remove deposits mechanically.

- Then treat with alcohol

- Check the bearing geometry:

- The surface must be completely flat.

- Eliminate any unevenness with fine sandpaper (600+ grit)

5. Installation of new guides

a) Positional alignment:

- Position the guide precisely

- Ensure perfect symmetry of all guides

b) Gluing process:

- Apply a minimal amount of epoxy glue

- Place the guide in the intended position.

- Pay attention to:

- Alignment angle

- Installation depth

- Even distribution of glue

6. Final processing and quality control

- After installation, allow 24 hours for polymerization.

- Carry out the check:

- Visual inspection

- Rotation test

- Checking axial symmetry

For the final check:

- Perform a nylon line test with minimal load

- Check that the rod is folding and extending properly.

Safety notes:

- Never use heat above 80°C.

- Avoid using metal tools in direct contact with graphite parts

- If you are unsure of the procedure, contact an authorized service technician.

This professional approach ensures the long-term functionality of your telescopic rod and optimal fishing performance. Each step should be carried out with complete care and precision.